PRODUCTS AND SERVICES

WE ARE PRODUCING 20,000 TONS PER ANNUM OF ELECTRICAL STAMPING AND FHP MOTOR PARTS FOR CONSUMABLE DURABLE INDUSTRY AS WELL AS AUTOMOTIVE / GENERAL ENGINEERING

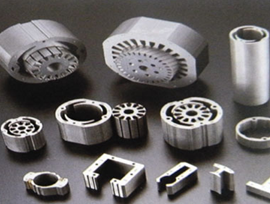

Electrical Steel Stampings

Stator Stacks

Interlocked and Auto-skewed Cores

Decarb Annealing

We have installed a Semi Continuous Decarb Annealing Furnace installed capacity of 400 M.T. per month for

Decarb Annealing and Bluing of Semi Processed Steel and thus converting the same into Electrical grade material suitable for Electrical

Stampings. Under this process the Stampings pass through different chambers which are electrically heated having positive atmosphere so

as to reduce the Carbon percentage and develop a uniform Grain Structure thereby reducing the Watt losses of the material.

Cold Rolled Semi Processed Lamination Steel is probably the most common material in use today. Ease of stamping and low tool wear help to

contribute to the low cost of finished laminations. Carbon steel is considered for applications where relatively high core losses are

acceptable (D.C. pole pieces, low duty cycles, etc.) and low first cost of the end unit is of primary importance. This material is always

annealed after stamping to develop optimum properties and remove the punching stresses. This adds little to the cost when done in a continuous

furnace, with controlled atmosphere and allows an oxide coat to be added to the surface to provide inter laminar resistance. The heat treatment

is somewhat critical and when properly annealed, modern grades of Lamination Steel have core losses equivalent to the lower grades of silicon steel.

Die Casting

From the very beginning Pooja Metal's determination to provide customers with full support has been realized by establishing our own die-casting facility for rotors and alloy components. The unit has been designed and developed to cater to the growing demand for die-casting of Alloy Components. The Company has installed CNC Machines along with other required equipment to manufacture finished components. In-addition to this the company also has Die Casting facilities with horizontal and vertical Die Casting machines installed.